Media library

Images

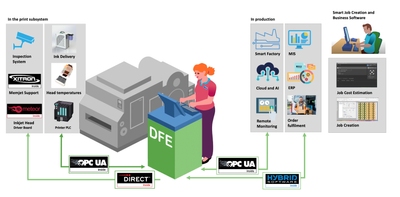

The SmartDFE from Hybrid Software Group

| Size | 922 KB |

| Dimensions | 2444 × 1206 |

Harlequin 13 introduces a new tiling feature specifically for high-speed digital printing

| Harlequin 13 introduces a new tiling feature specifically for high-speed digital printing. | |

| Size | 735 KB |

| Dimensions | 1772 × 1317 |

Ditch the disk with Direct

| Direct is a new graphics pipeline that sends data directly to the printhead electronics without ever touching a disk. | |

| Size | 2,030 KB |

| Dimensions | 3000 × 2250 |

PrintFlat has removed banding

| PrintFlat removes directional non-uniformity or banding from inkjet output to achieve fine granularity on single-pass and multi-pass applications. | |

| Size | 1,010 KB |

| Dimensions | 2362 × 1294 |

Before PrintFlat is applied

| Before PrintFlat has removed directional non-uniformity or banding from inkjet output. | |

| Size | 1,580 KB |

| Dimensions | 2362 × 1294 |

PDF Processing Steps

| PDF Processing Steps promises the ability to control technical marks without needing to analyze each file and create a different setup for each job. | |

| Size | 84.2 KB |

| Dimensions | 510 × 546 |

Print before PrintFlat™ is applied

| Print showing banding before PrintFlat™ has been applied. | |

| Size | 408 KB |

| Dimensions | 1609 × 1123 |

Print showing PrintFlat™ applied

| With PrintFlat™ applied. | |

| Size | 1,050 KB |

| Dimensions | 1619 × 1214 |

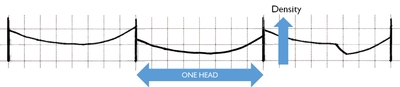

ScreenPro corrects the inkjet smile

| ScreenPro with PrintFlat technology reduces non-uniformity, commonly known as the inkjet smile. | |

| Size | 88.1 KB |

| Dimensions | 1331 × 291 |

Uncorrected file

| Uncorrected file. | |

| Size | 5,410 KB |

| Dimensions | 5326 × 3551 |

Calibrated with ScreenPro

| Image showing file corrected with ScreenPro. | |

| Size | 6,370 KB |

| Dimensions | 5279 × 3519 |

The Inkjet Smile

| ScreenPro with PrintFlat technology reduces variations in ink density, commonly known as the inkjet smile. | |

| Size | 640 KB |

| Dimensions | 5209 × 4167 |

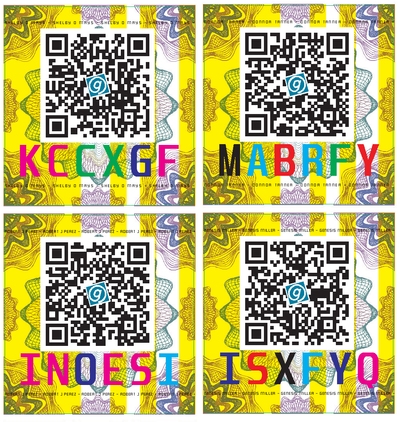

Secure tickets generated with bar-code support in Harlequin Core

| Size | 1,310 KB |

| Dimensions | 1023 × 1078 |

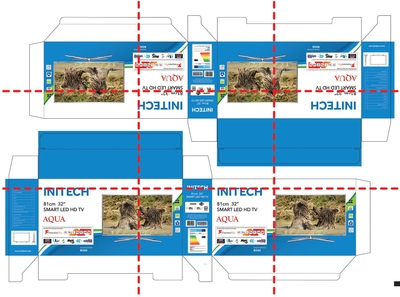

This folding carton shows the use of dynamic overlays for variable data in Harlequin Core

| Size | 540 KB |

| Dimensions | 2305 × 2545 |

Advanced Inkjet Screen: Pearl

| Counteract streaking on output from inkjet presses with Pearl, one of two new advanced inkjet screens from Global Graphics Software. | |

| Size | 2,040 KB |

| Dimensions | 3004 × 5433 |

Advanced Inkjet Screen: Mirror

| Avoid orange peel mottle on poorly wettable substrates with Mirror, one of two new Advanced Inkjet Screens from Global Graphics Software. | |

| Size | 635 KB |

| Dimensions | 3000 × 2205 |

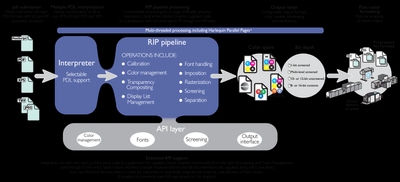

Harlequin RIP core

| Size | 227 KB |

| Dimensions | 1780 × 812 |

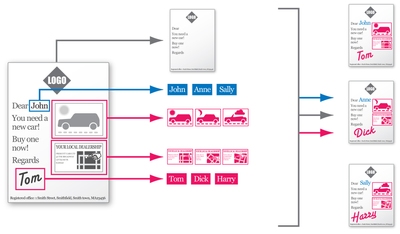

Harlequin VariData schematic

| Size | 399 KB |

| Dimensions | 1800 × 1054 |

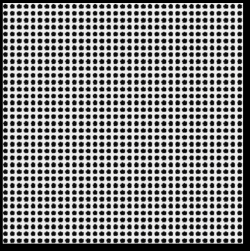

Multi-level screening - clean grid

| Size | 147 KB |

| Dimensions | 250 × 251 |

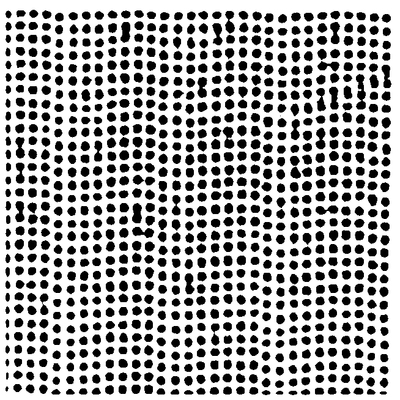

Multi-level screening - uneven grid

| Size | 32.9 KB |

| Dimensions | 654 × 654 |

1/4 Irregular drop positioning leads to drops ‘randomly’ coalescing on the media

| Size | 74.7 KB |

| Dimensions | 512 × 384 |

2/4 Irregular drop positioning leads to drops ‘randomly’ coalescing on the media

| Size | 52.7 KB |

| Dimensions | 512 × 384 |

3/4 Irregular drop positioning leads to drops ‘randomly’ coalescing on the media

| Size | 58 KB |

| Dimensions | 512 × 384 |

4/4 Irregular drop positioning leads to drops ‘randomly’ coalescing on the media

| Size | 55.1 KB |

| Dimensions | 512 × 384 |

1/2 Original image These microscopic effects cause visible artifacts, often described as mottling or streaking

| Size | 3,020 KB |

| Dimensions | 2323 × 1290 |

2/2 These microscopic effects cause visible artifacts, often described as mottling or streaking

| Size | 704 KB |

| Dimensions | 1181 × 656 |

People

Justin Bailey

| Managing Director | |

| Size | 9,290 KB |

| Dimensions | 2760 × 3249 |

Eric Worrall

| Vice President of Products and Customer Success | |

| Size | 11,100 KB |

| Dimensions | 2760 × 3249 |

Peter Goodwin

| Group Finance Director and Company Secretary | |

| Size | 9,950 KB |

| Dimensions | 2760 × 3249 |

Ben Gilbert

| Engineering Manager | |

| Size | 759 KB |

| Dimensions | 2760 × 3249 |

Matt Gosnell

| Chief Information Officer | |

| Size | 353 KB |

| Dimensions | 1143 × 1210 |

Videos

Mako Core 8 and Apex: Taking rendering to the next level

As featured on WhatTheyThink, 30th July 2025

Global Graphics has been licensing the MAKO SDK to software developers and equipment manufacturers for years with great success. However, this new APEX solution brings a smarter and faster solution to the marke…

Apex Multipage Demo

Following on from his first demonstration of Apex, David Stevenson, product manager at Global Graphics Software, is back with a second video — this time showing how Apex handles multi-page rendering.

Apex™ is a new groundbreaking rendering technology de…

Demonstration of an ink delivery system and OPC UA connectivity

Jason Hook, senior project manager in the Technical Services team at Global Graphics Software, shows how an Ink Delivery System (IDS) can be monitored and controlled using OPC UA and a SCADA (Supervisory control and data acquisition) application. The prot…

Seeing is believing: Introducing Apex, the world's first fully GPU-native PDL renderer

Apex™ is a new groundbreaking rendering technology designed to boost performance and reduce costs. Built for high-performance, cross-platform applications, Apex runs entirely on the Graphics Processing Unit (GPU) delivering exceptional high-speed renderin…

Choosing a Print Software Development Kit (SDK)

A Print Software Development Kit (SDK) is a specialized software library designed to meet the unique needs of the print industry. In this film, product manager David Stevenson highlights the key aspects to consider when choosing a Print SDK, including spe…

Inkjet printing in smart manufacturing: driving mass customization and sustainability

Find out more about the challenges and opportunities that inkjet printing will bring to smart manufacturing - from mass customization to being more sustainable.

Smart factories are designed to autonomously run the entire production process and this will…

Maximizing press productivity: the crucial role of predictable print jobs in achieving top speeds

The print market is increasingly moving to digital. Digital presses are getting faster, wider, higher resolution with extended gamut color becoming common place. Digital presses are also moving towards fully variable data with mass-produced personalized o…

Choosing a Digital Front End for your high-speed, single-pass, roll-to-roll inkjet press

The Digital Front End (DFE) is a crucial component in inkjet printing solutions, acting as the nerve center that controls and coordinates the entire printing process. This film explores the role of the DFE in various aspects of inkjet printing, including …

See the SmartDFE at Fespa 2022, Berlin

Justin Bailey, managing director at Global Graphics Software, highlights SmartDFE at the Fespa 2022 exhibition in Berlin. SmartDFE is a full software and hardware stack that gives you everything you need to add print to the fully automated smart factory. …

Smart QI - the quality inspection system for high-speed digital printing

As the use of variable data, press speeds and resolutions grows, the need to inspect the print for defects before it comes off the press and goes into finishing and converting is essential.

In this film, David Stevenson, product manager for Mako™ chats t…

How to meet the challenge of printing vast amounts of data at speed with traditional print workflows

If you're looking for software to power your first or next digital press, it will need the right kind of software engine that isn't based on disk technology and drives your digital press electronics directly.

In this film, product manager Ian Bolton expl…

Variable data printing and Harlequin VariData

Global Graphics Software's distinguished technologist Martin Bailey explains what variable data printing is, how it works, and why Harlequin RIPs with Harlequin VariData™ in them can help you build a digital front end (DFE) for a digital press that will d…

Working with spot colors in Harlequin Core

In this film, distinguished technologist Martin Bailey demonstrates how to work with spot colors in Harlequin Core. Martin offers useful tips and tricks and uses sample files and configurations to demonstrate:

- Separation and Emulation

- Adjusting Emulat…

Vector-based transparency flattening with Mako Core

Mako product manager David Stevenson gives a short demonstration of the vector transparency flattening feature in Mako Core. Read more about vector-based transparency flattening on our blog:

How to retain print quality with vector-based transparency fla…

Presentations

Streaming print data directly to printhead electronics

Sending print data directIy to the printhead electronics makes it possible to achieve blistering speeds even with variable data when every item is different. Can you maintain optimum quality too? The benefit is significantly improved productivity because …

Correct color on inkjet means uniform color; profiles are not enough

This presentation, made at the recent Fespa 2019 in Munich, shares some of the insights and advances we’ve achieved over the last few years as we’ve worked with many inkjet press vendors to increase their output quality.…

Has inkjet really achieved offset quality?

From about the middle of last year, the consensus seemed to be that inkjet had finally attained the same quality as offset lithography or flexography. How has that consensus been reached when the areas that inkjet still finds difficult are things like lar…

The best of both worlds - High quality, reliability and speed

Is it really possible to achieve blistering speeds with variable data and maintain optimum quality? How do you keep the presses running with no waiting time when every printed piece is different from the next? How do you mitigate artifacts like banding, o…

Introducing ScreenPro™ with PrintFlat™

ScreenPro offers high-speed halftone screening & quality improvement for inkjet printers and presses…

Global Graphics IJCUSA 2018 - Avoiding the orange peel

At the recent Inkjet Conference in Chicago Global Graphics CTO Martin Bailey provided an update on mitigating texture artifacts on inkjet presses using halftone screens: streaking, coalescence, tone steps and the dreaded orange peel mottling.…

Avoiding the orange peel - The IJC 2017

Global Graphics CTO Martin Bailey presents an update on mitigating texture artifacts on inkjet presses using halftone screens: streaking, coalescence, tone steps and the dreaded orange peel mottling. But improved screening reveals other imperfections, a b…

What Customers Want

Gary Fry, CEO at Global Graphics, presents 'What the Customer Wants - how software choices affect the performance of your press.' at the IMI Ink Jet Printing Conference 2017.…

Intelligent software is as important a component of your digital press as any hardware

Intelligent software makes a huge difference to the commercial success of your inkjet press. That's the message that Martin Bailey, CTO at Global Graphics Software, discusses at the annual Inkjet Conference on 5th and 6th October 2016.…

Fundamentals for Label and Packaging; Labelexpo 2016

Today the inkjet industry is exploring how to achieve optimal, repeatable image quality. Brand owners expect high-quality output across all their communication channels. Yet many press manufacturers are frustrated that they are not able to achieve the q…

A breakthrough in inkjet quality - Harlequin Multi-Level Digital Screening

Harlequin Multi-Level Digital Screening is a new technology from Global Graphics Software. It has been specially developed so you can print confidently on challenging media and at higher speed, allowing you to expand into higher quality (higher margin) ap…

Better ways to make PDF and PDF/VT for direct mailing

There are lots of guides on how to design direct mail jobs to increase response rates but nothing to help with the actual construction of a PDF for optimal production. Yet in 2011 an Infotrends study found that 85% of print service providers use PDF for …

RIPping through data - Challenges faced in the digital front end

"The challenge isn't just to be fast enough", says Global Graphics' chief technology officer, Martin Bailey. "The real challenge is to achieve that goal without incurring an uneconomically high cost for the bill of materials to buil…

RIPping through data - Challenges faced in the digital front end

"The challenge isn’t just to be fast enough", says Global Graphics' chief technology officer, Martin Bailey. "The real challenge is to achieve that goal without incurring an uneconomically high cost for the bill of materials to build th…