Smart Control

Experience the power of a fully customizable Digital Front End (DFE) that adapts to your brand requirements. This solution provides a seamless entry into the market, enabling swift integration. Operating in server (headless) mode, it also effortlessly complements your existing front end setup and integrates with the OPC UA API, enhancing connectivity.

Smart Print Controller (SPC)

Your brand, your controller: Customizable branding with SPC

The Smart Print Controller (SPC) goes beyond the standard by offering a fully customizable user interface and installer. This means you can personalize the application name, icons, splash screen, and even the application colors. Recognizing the pivotal role software plays in differentiating your digital press, it's paramount to have your brand and product identity prominently showcased to press operators. This level of branding ensures your distinct identity remains front and center in the user experience.

Accelerate market entry

Harness the SPC interface and plugin SDK

Use the SPC interface to speed up your market entry. The SPC user interface is designed to be easily enhanced with the provided SDK, allowing quick addition of new features. If you're short on development resources, our Technical Services team is here to help. Through our Break Through Service, they can develop new plugins for you, smoothing your path to launching your product.

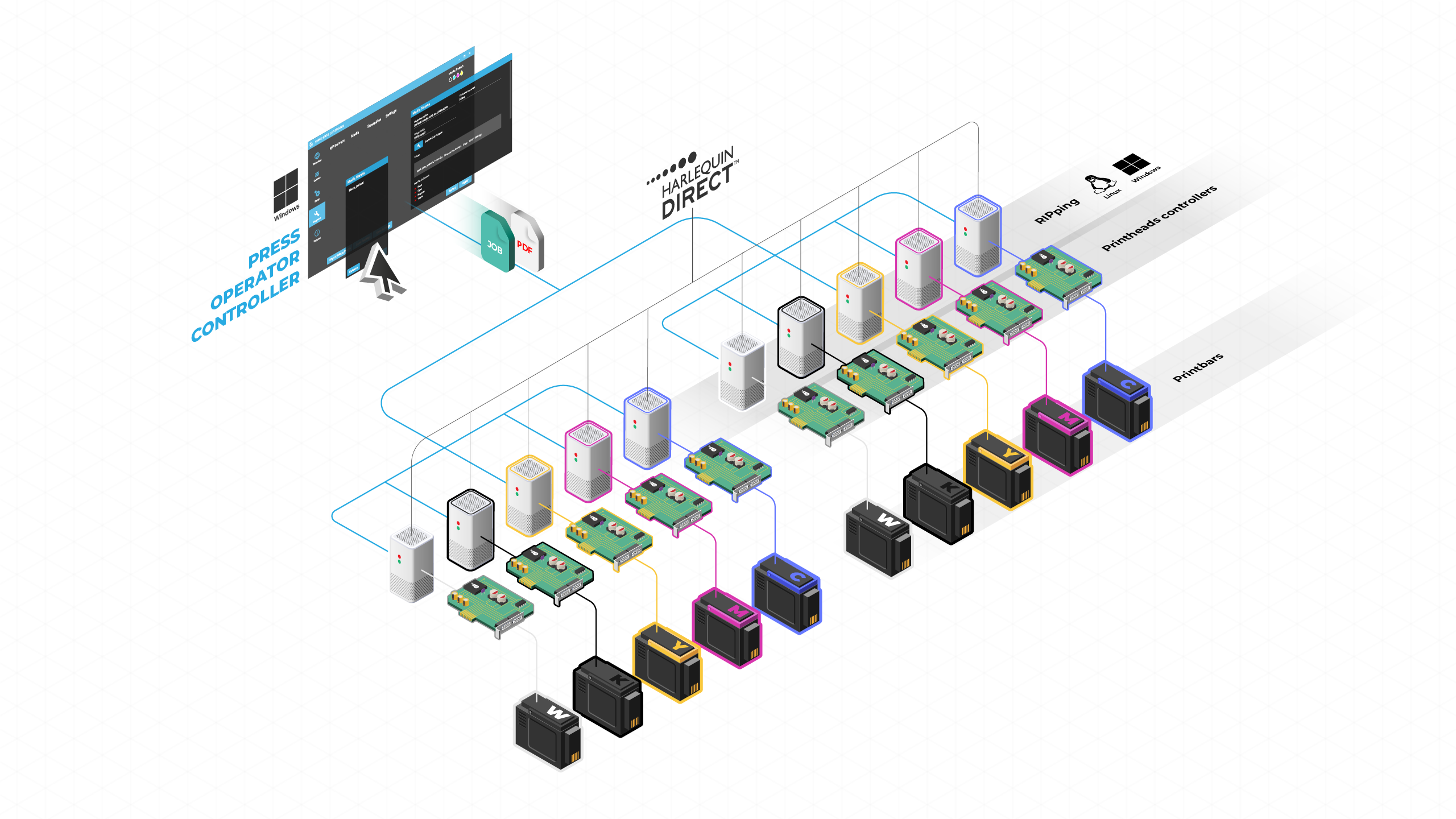

Scalable to support extended gamut and duplex

SmartDFE offers effortless scalability. With just a configuration change, you can switch between operating it on a single PC or using multiple RIP Server PCs, one for each print bar. Adding features like extended gamut, spot colors or duplex printing is straightforward. You can also customize each print bar individually, such as using a higher bit depth for black or opting for a lower resolution for white or varnish. This flexibility allows for tailored performance to suit diverse printing needs.

Visualize before you print

Exploring the Job Editor's insights

To preview a job before printing, simply click the small pencil icon next to the job. This action opens the Smart Job Editor, an integrated PDF viewer. In this viewer, operators can thoroughly inspect the job and even modify the job ticket, such as choosing specific pages to print. But the Smart Job Editor offers more than just basic viewing: it gives operators detailed insights into the job, including identifying and interacting with spot colors. Operators can choose to show or hide each color individually, allowing them to see the impact of each color on the overall job.

Customizing spot colors: Flexibility in LAB and Device Space adjustments

If a spot color is outside the press's color gamut, an alert triangle notifies the operator. With advanced ColorLogic technology, operators can easily rectify this: they can either auto-adjust the spot color to fit the gamut or manually tweak it using LAB color space or Device Space. This is also applicable to extended gamut settings for accurate color representation. Modified spot colors can be saved either within the job or in the target Smart Media Definition (SMD), allowing consistent application in future jobs on the same media, streamlining the workflow.

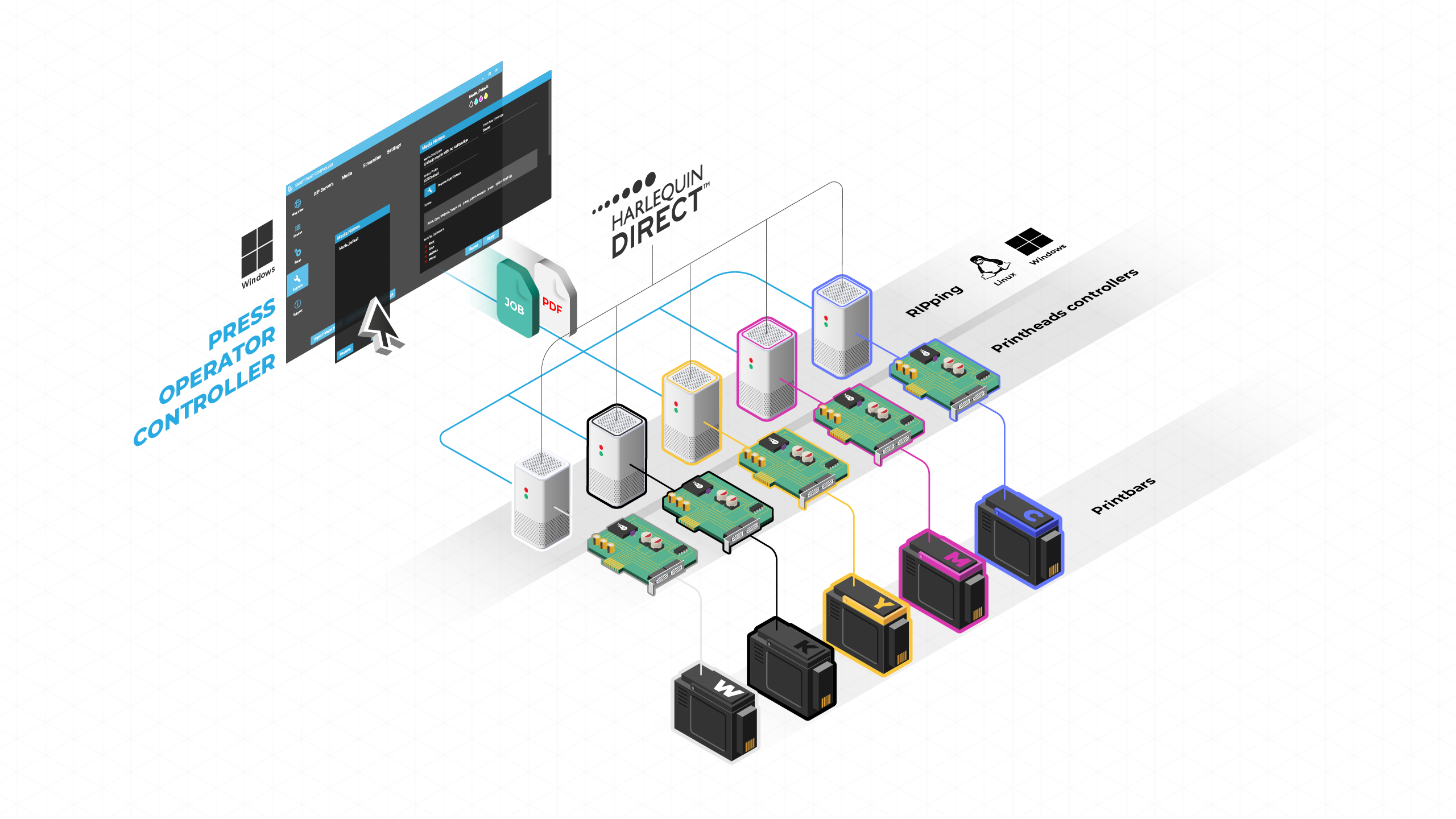

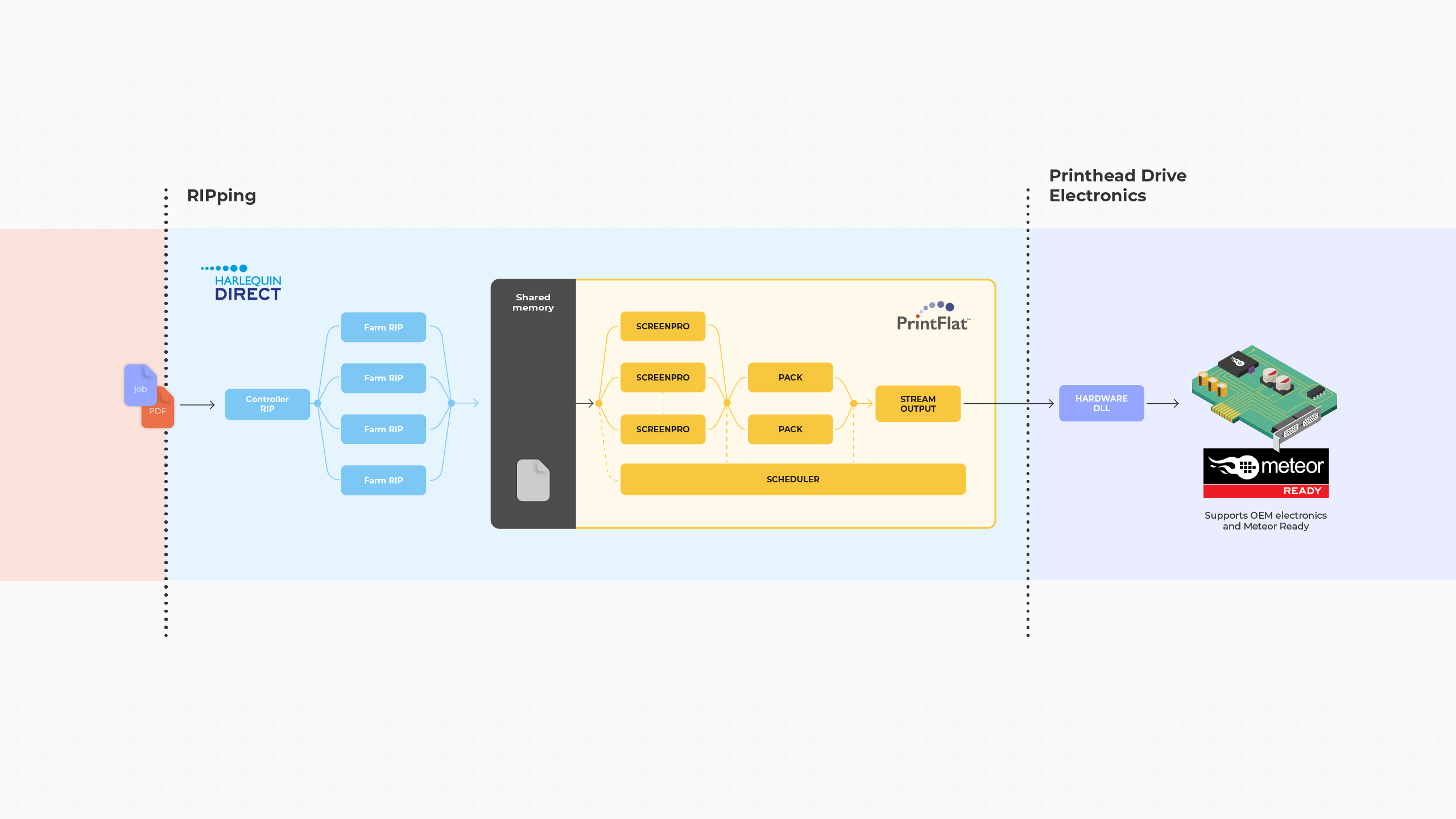

Harlequin Direct

Smart Print Controller (SPC) is powered by our innovative Harlequin Direct™, which represents a significant advancement in inline RIP technology. It is designed for unprecedented speeds and scalability, marking a new milestone in performance. This solution offers immediate first-page output by directly RIPping PDFs to printhead drive electronics, thus eliminating the need for RIPping ahead. Our distinct edge lies in our independence from third-party core RIP solutions, as we have developed our proprietary Harlequin Core™. This core is widely recognized for its over 30 years of excellence and is acclaimed as the world's fastest RIP core.

Key features of Harlequin Direct:

- Uses multi-core and multiple PC configurations for ultra-high-speed and highly scalable RIP processing

- Delivers instant first-page output, directly RIPping PDFs to printhead drive electronics, removing the need for preliminary RIPping

- Self-reliant with our in-house Harlequin Core, eliminating dependence on external core RIP solutions

- Compatible across multiple platforms, including Windows and Linux (Ubuntu and CentOS)

- Offers specialized plugins tailored for unique printer functionalities, such as bar splitting and integration with inspection systems

- Includes an Output Plugin SDK allowing new output formats and inline functions to be developed

Smart Job Cost Estimator

The Smart Job Cost Estimator™ (SmartJCE) is a ground-breaking tool that helps your printer's sales people to accurately estimate the costs of ink, substrate, and services for any job. With SmartJCE, you can easily calculate the cost per label and the total project cost from a press-ready PDF. What makes it special is that it works on its own, without needing a connection to your printer. This makes it perfect for providing precise job cost estimates remotely, even outside your customer's print shop.