Smart Quality

In today's printing landscape, achieving top-quality prints and precise colors often relies on skilled print operators. However, there's a shortage of these experts. This is especially noticeable in industries integrating print into broader processes, where non-specialists take on printing tasks. To address this, Smart Quality™ combines advanced technologies like ColorLogic, ScreenPro™, and PrintFlat™ into a user-friendly system, making it easier for any operator to achieve excellent print quality.

Quality printing without the complexity

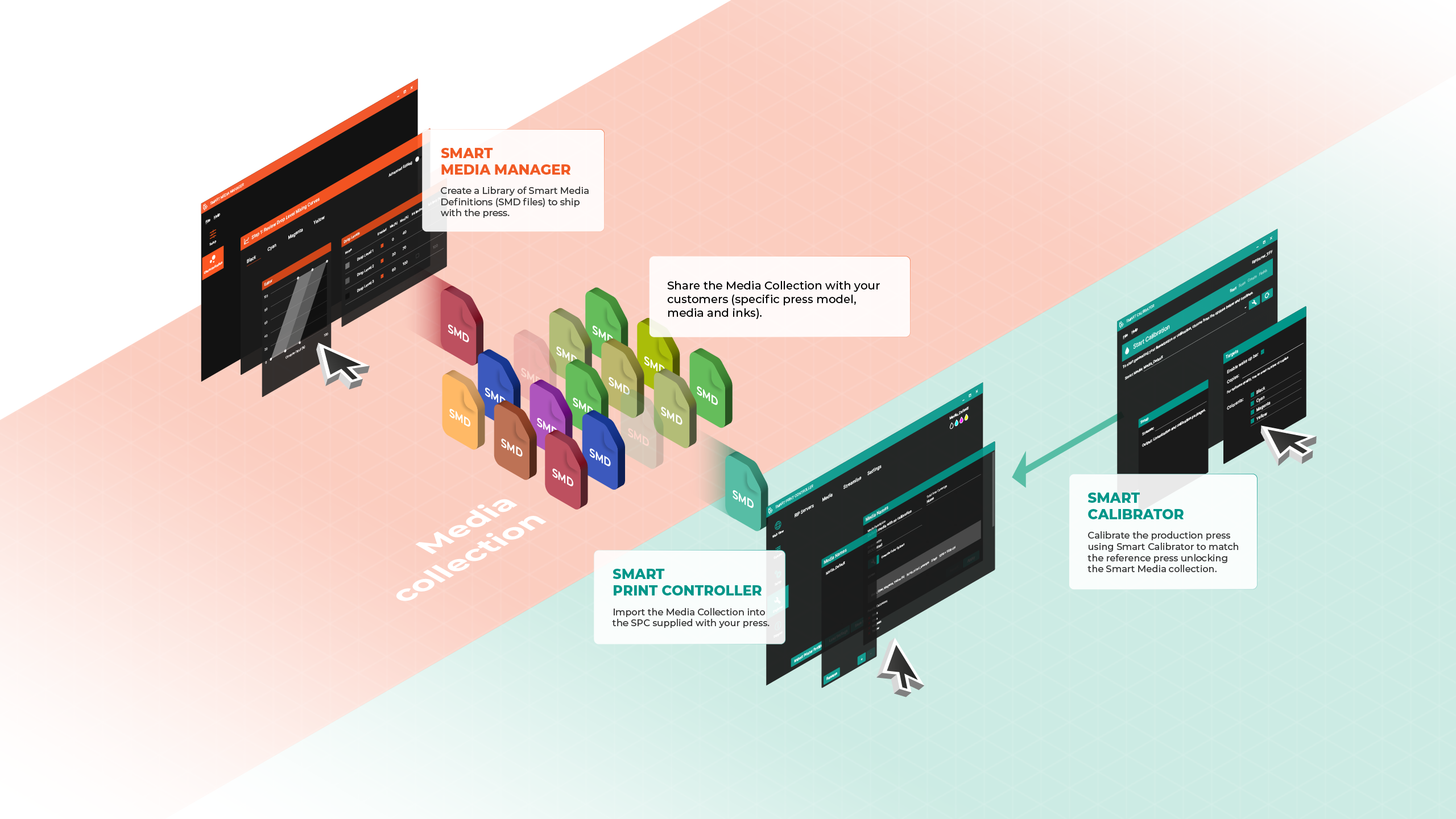

SmartMedia™ aims to simplify high-quality inkjet printing, reducing reliance on operator expertise in color science. As inkjet presses become more common, integrating expertise into the software is crucial. Your role is to optimize a reference press for each media type. These settings are then shared with operators, who use a simple tool to align their presses with your standard, ensuring that all media are adjusted to achieve top quality.

Smart Media Manager is a wizard that helps you set up the following settings:

- Choose Screen tiles to use (can be customized)

- Drop size transition

- Dot gain

- Density curve control (Linearization)

- Gray balancing (Optional)

- Reference (“Golden”) state

- ICC profile generation (using ColorLogic technology)

- Device link profiles

- RIP color settings

- Nozzle correction settings

- Spot color overrides

- Pinning configuration

Empowering operators

SmartDFE's integration of ColorLogic technologies

The SmartDFE incorporates ColorLogic technology within its standard tools. The Smart Media Manager uses the ColorLogic SDK, facilitating easy creation of profiles suitable for operators without extensive color science expertise. Additionally, we employ ColorLogic's CMM and spot handling technology in the 'Job Editor' feature of the Smart Print Controller. For operators seeking greater control over ICC profile generation, optional full licenses for CoPrA and ColorAnt are available for purchase.

Tackling density variations in inkjet printing with PrintFlat

Inkjet printheads often show uneven density, known as the 'smile' effect, which worsens with wear and stitching overlaps, causing visible banding in prints. This issue limits print quality, sometimes necessitating discounted sales. Current methods like drive voltage tuning offer limited and complex improvements. PrintFlat technology provides a more effective solution by calibrating each printhead’s 'fingerprint' in the screening process, allowing for individual nozzle compensation. This enhances print quality without sacrificing speed, improving output and service efficiency.

Before PrintFlat |  After PrintFlat |

Next-level print quality with PrintFlat Advanced Inkjet Screens

PrintFlat Advanced Inkjet Screens™ (AIS) are a new evolution in Harlequin Dispersed Screens™, tailored for digital inkjet printing. These screens address common defects like repeat patterns, moiré, worming, mottle, noise, and color convergence. PrintFlat AIS offers three types:

- Mirror: Counters mottling or "orange peel" effect in solid colors, particularly on non-absorbent or poorly wetting substrates.

- Pearl: A fine dispersed (FM) screen for natural images, it disrupts artifact directionality, reducing chaining and streaking on absorbent substrates.

- Opal: Combines Mirror and Pearl to reduce graininess and high-frequency streaking, especially with UV-cured inks on difficult substrates.

Custom Screen Design Service

PrintFlat AIS screens are flexible, fitting different printers, printheads, and applications. They can be customized or form the basis for unique screens. The Custom Screen Design Service lets you develop screens that meet your printer's specific needs and application requirements. This service is crucial for consistent output quality, aligning analogue and digital prints, solving particular artifacts, improving ink efficiency, and enabling special effects.