Case Study

HP PageWide Industrial raises the bar with the Harlequin RIP®: a global leader in the manufacture of inkjet presses, HP constantly pushes the boundaries and sets new standards to offer its customers the highest level of quality and performance, and the Harlequin RIP plays a key role in this.

AN OBVIOUS CHOICE

When HP Inc set up what was to become its PageWide Industrial division in 2008 to develop presses for the industrial inkjet market, theHarlequin RIP was the obvious choice to use at the core of its Digital Front End.

Tom Bouman, worldwide workflow product marketing manager at HP explains: “Harlequin came with a good reference: HP software engineers joining PageWide Industrial had been using it successfully for several years at HP Indigo to drive its digital presses for photo book printing. They were familiar with the product and knew it was a reliable solution with a track record for high quality and high speed. With our industrial inkjet division, we planned to take inkjet to a new level of speed and performance, and we had no doubts that Harlequin could handle that.”

The Harlequin RIP also offers a number of important features:

SCALABILITY

HP PageWide Industrial wanted a fast RIP that was scalable to meet the demands of industrial inkjet printing. The HP scalable printhead technology was perfect for creating a broad family of press configurations and a philosophy of upgrading existing platforms vs. replacing them for future growth. The Harlequin Scalable RIP delivered a complete range of RIP/server configurations to bring these high-quality, highly robust solutions to market quicker, with minimal development effort for initial integration.

KEY FACTS

- Harlequin drives the full range of PageWide T-series presses for industrial inkjet from 20-inch up to 110-inch and the full range of HP Indigo commercial, label and packaging presses, as well as the HP Scitex C500 corrugated post-print press.

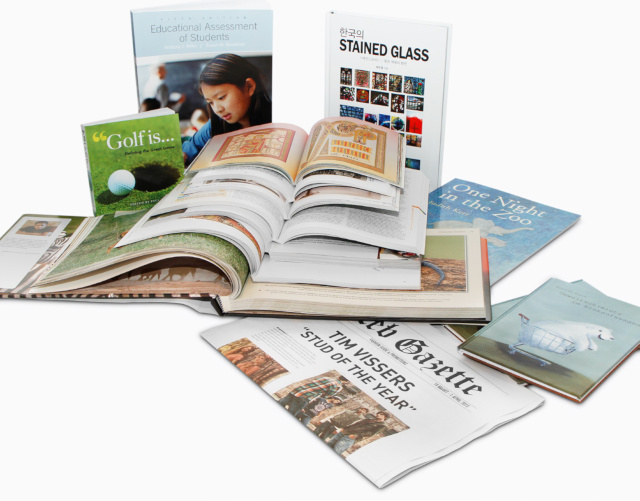

- Applications for the HP PageWide Industrial presses include direct mail, publishing, commercial and corrugated packaging.

- The T1190 press is the market’s most productive digital packaging press today. Driven by the Harlequin RIP, it requires approximately 45GB of raster data every second to keep it running at engine speed. With linear print speeds of up to 1,000 feet per minute, it can produce up to 551,000 square feet or 51,206 square meters per hour.

“We’ve always been at the high end of performance in the industry - we’ve always pushed ourselves and Harlequin has been able to do that for HP.”

FAST VARIABLE DATA PROCESSING

Direct mail and transactional print have always relied heavily on variable data but publishing, commercial print, and packaging are trending toward using more variable data as versioning, short runs, and personalization become more popular. Some applications add unique ID codes to each piece for security tracking, gray market protection, and anti-counterfeiting. Harlequin’s VariData feature is extremely important, as it accelerates the processing time of PDF files containing variable data while not affecting performance. Tom says: “In the early days some of the nuances of the way people created the data and features like transparencies used to be quite a challenge and slow the printing process down. Since that time, the RIP design has improved to be less sensitive to many file structure issues and users are more educated in creating files for high-speed printing. In fact, we have contributed to a guide produced by Global Graphics about how you can create variable data PDF files that won’t slow the press, and we’ve found over the years that publications like this have helped iron out a lot of performance issues.”

Packaging is trending toward using more variable data as versioning, short runs and personalization become more popular.

The T-Series presses ensure high-quality results on corrugated packaging, from brown boxes to premium-designed packages.

THE BEST IN COLOR

“Good color management tools are also very important in our markets,” continues Tom. “We need to be certain we can achieve accurate brand color emulation, and high-quality image reproduction, and the feature ensures this.”

CONSTANTLY EXPANDING

Since deploying the Harlequin RIP all those years ago, the company has expanded to meet ever-increasing customer demands as the market has developed. “We’ve always had a good relationship with the team at Global Graphics Software and we’ve worked closely over the years to ensure we continue to offer the highest performance in terms of speed and quality,” adds Tom.

Today, the Harlequin RIP Core is at the heart of all the PageWide T-series presses, driving the HP Production Elite Print Server digital front end. Presses range from 20-inch for commercial printing, through to the large 110-inch (T1100 series) printers for high-volume corrugated pre-print, offering a truly scalable solution that sets the standard in performance and quality.

ABOUT HP PAGEWIDE INDUSTRIAL

HP Inc. (NYSE: HPQ): Famously started in 1939 in a garage in Palo Alto, California by Bill Hewlett and Dave Packard, HP continued to innovate new and disruptive technologies. Development of thermal inkjet began in 1978 and the ThinkJet printer was introduced in 1984. Inkjet continued to evolve, a scalable printhead was created, and at drupa 2008 the first HP Inkjet Web Press was introduced. A vertical integration strategy advances innovation across all aspects of printing solutions. Components of the HP PageWide Web Press (web transport, printheads, image processing, software, RIP servers, inks, dryers, and media) are developed together, assuring the best possible holistic solution. Economics of scale, upgradeability, longer asset life, and reduced replacement cost deliver a solid return on investment.

Today, HP Page Wide Industrial is a leader in high performance, offset quality inkjet systems and workflow solutions for industrial print manufacturing providers. Applications include general commercial print, direct mail, transaction & transpromotional, corrugated packaging, and print on demand book production. Scalable from simple offset replacement to the most complex variable data content, these presses have now produced over 600 billion pages since its inception … and growing.