Smart Performance

In printing, different Raster Image Processing (RIP) complexities can cause varying RIP times, even for pages that look similar. Slow pages are less problematic in setups like sheet-fed presses or when the job is RIPped to disk before printing. However, in high-speed, single-pass, roll-to-roll presses using an inline RIP, a slow page can cause underruns, disrupting operations and leading to waste. Addressing this, our patented Streamline Autotune™ technology leverages artificial intelligence to provide operators insights on achieving press RIP speed reliably, reducing uncertainties and the risk of operational disruptions and waste.

SmartDFE compatibility with diverse PDF creators

When integrating PDF creators with SmartDFE, the choice is crucial. While reliable options like Hybrid Software's STEPZ® ensure consistent results, other alternatives might produce varying speed and quality. Two PDFs might look the same, but their structure can differ greatly. To achieve maximum print speeds, you can either use trusted tools like STEPZ or add a component that assesses each PDF job's printability, helping to determine feasible printing speeds and prevent potential inefficiencies.

Streamline's AI-accelerated speed estimates

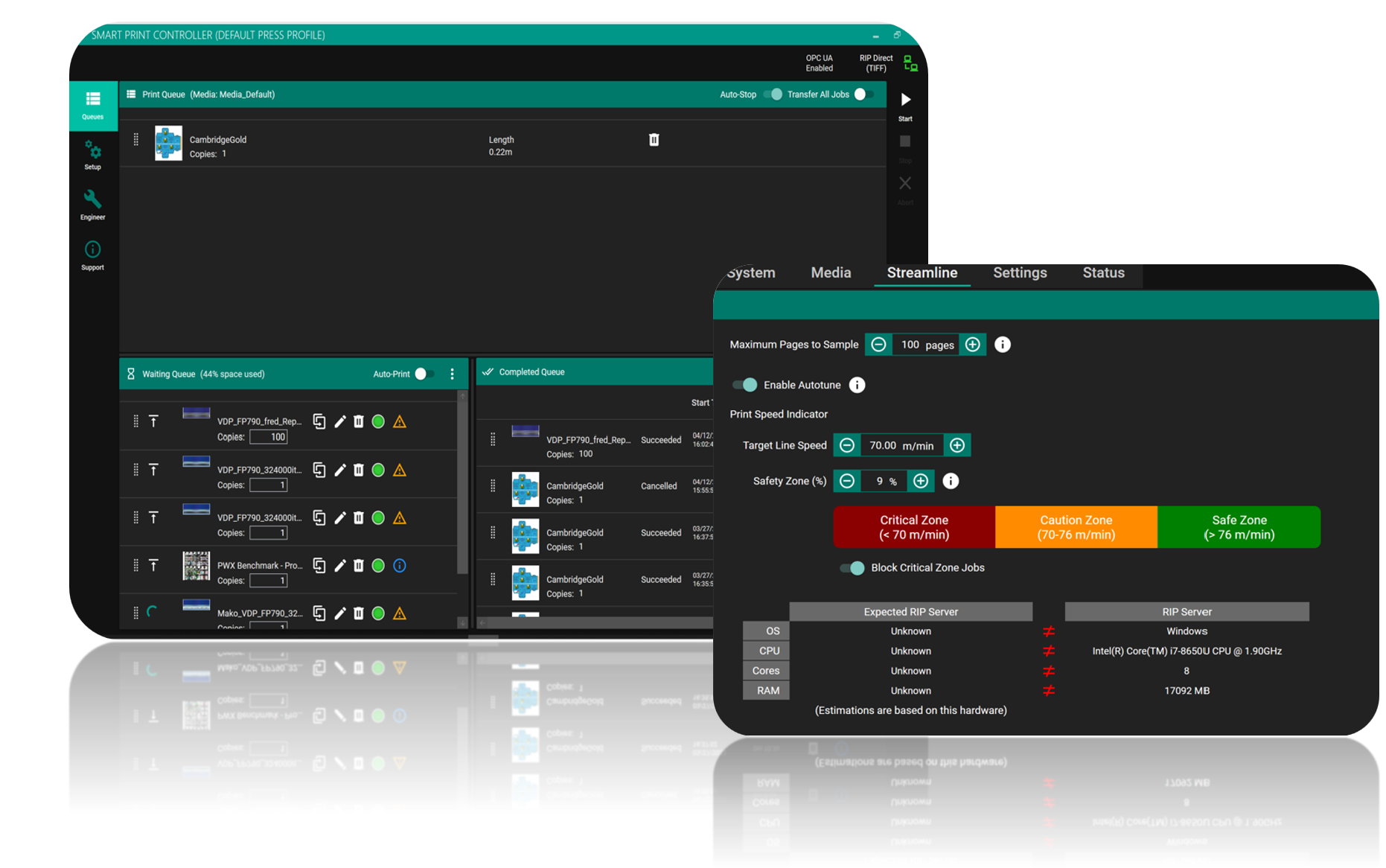

Using advanced AI, Streamline accurately predicts the feasible line speed for each job, displayed as a color-coded indicator next to the job in the "Waiting" queue. Green indicates the job can run at target speed without issues, amber suggests caution at target speed, and red warns of potential streaming problems with SmartDFE. Facing a red indicator, operators can either RIP the job ahead to contone ("Rip and Hold") or send it back for refinement. This system aids operators in making informed decisions for optimal production flow. Looking forward, these AI-driven speed estimates could automatically set the press's speed, advancing towards seamless automation via the OPC UA interface.

Streamline Autotune

Elevating performance beyond limits

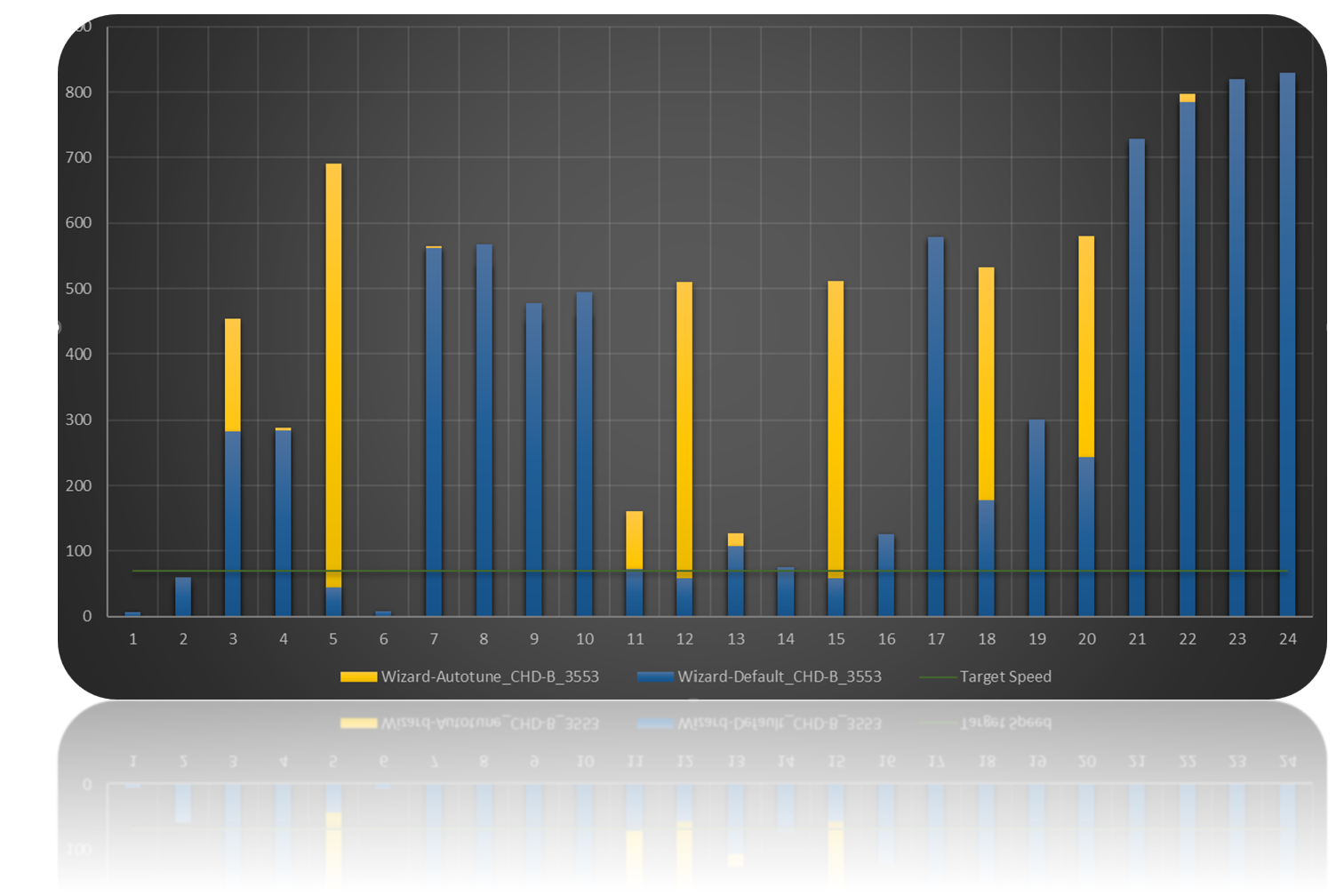

When Streamline Autotune detects a job not meeting its target speed, it promptly optimizes performance by adjusting both the job and RIP, using AI data and its deep understanding of the Harlequin Core™. This process benefits from our unique control over both RIP and PDF analysis technologies, allowing for in-depth PDF analysis and modifications at the RIP's core code level. This synergy enables substantial performance improvements. After adjustments, the system updates its performance indicators, informing the operator that the job is now ready for efficient streaming.

Streamline fingerprint report

Operators using SmartDFE can request a fingerprint report to analyse job performance. The report highlights the job's slowest page and provides a performance analysis in two charts. The first chart shows the timing of key operations for 20 pages surrounding the slowest one, aiding in identifying complexity variations and pattern recognition. The second, a pie chart, details the slowest page's RIP processing time across various tasks (trained on 10,000 PDF operations). These insights enable job creators to enhance performance by modifying or eliminating time-intensive PDF operations, thereby recreating the job more efficiently.

Colossus

Our internal performance data powerhouse

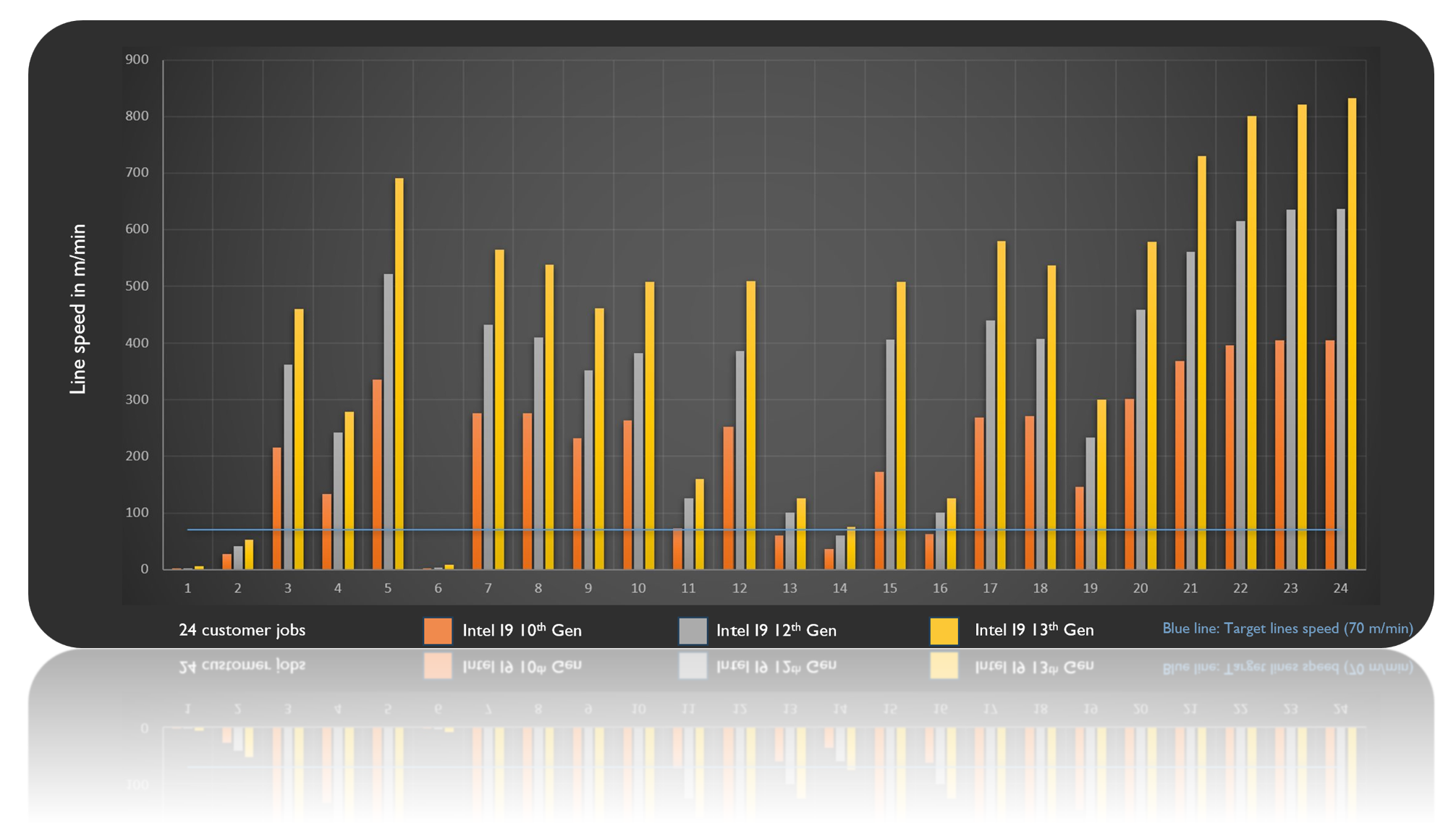

Our in-house system, Colossus, comprises six high-powered Intel i9 CPUs of various generations to enhance our RIP (Raster Image Processing) operations. Monitored via OPC UA and displayed on a SCADA system, it tracks performance metrics across diverse customer setups. Data, shown on color-coded dashboards, informs us about ongoing tests and Streamline AI training. This efficient setup accelerates research and improvements, crucial for evolving our Streamline and RIP performance.